Data Reduction

Efficiency

No need to learn a new system: The user interface for Data Reduction is identical to the vibration control software. This means you can create tests and record measurement data seamlessly within the same workflow.

Safety

Built-in protection mechanisms such as limit monitoring keep your measurements safe at all times. You can rely on stable data acquisition, even under demanding test conditions.

Flexibility

One system for all your test stands: Data Reduction operates independently of the controller and works with third-party systems as well as with m+p controllers. Whether you run multiple shakers or different test setups – the solution moves with you.

Quality

Achieve precise and synchronized data through COLA signal, with high sampling rates and dependable performance across large channel counts. Data Reduction delivers trustworthy insights and transparency you can rely on for every analysis.

Flexibly scale the channel count for your vibration test

Flexibly record large numbers of channels

With scalable hardware from 16 to 1280 channels, the data reduction system is ideal for extensive measurement tasks - even where the controller cannot cover all channels.

Independent data acquisition - even with third-party controllers

Acquire measurement data synchronously with the control - even with third-party controllers. Ideal for changing requirements, different shaker setups and independent test setups.

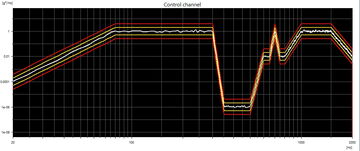

Frequency synchronization via COLA signal

The COLA signal (Continuous Output Level Amplitude) ensures precise frequency synchronization between control and data reduction during sine tests.

Integrated protection mechanisms - self-sufficient and secure

Limit values can be defined directly in the data reduction system. If a limit is exceeded, a digital output activates the safety shutdown via the controller - without delay.

Standardized user interface - efficient workflow

The user interface, settings and operating logic correspond to the m+p VibControl control system - ideal for familiar working without additional training.

Flexible use across multiple test stands

The system can be used between different shakers as required - particularly economical for rare high-channel requirements.

Upgrade to

VibControl 2.19

Discover how the new features boost your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for data reduction

Useful additional modules

Sine testing services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Data Reduction resources

Data Reduction – FAQ

Data reduction is how you can synchronise a second- or third-party system to the controller to act as a data acquisition with no active feedback into the control loop. With sine testing, this synchronization is done via a constant output, level amplitude signal (COLA) for the tracking filter.

This can be useful if you have multiple systems and need to combine them to expand your channel count, adding more measurement points or to capture data in preferential formats belonging to a particular system.

Absolutely! With shock and random modes this is easy as it can be done with a simple trigger. With sine mode, an industry standard signal called COLA is required for the tracking filter on the data acquisition system.

During a sine sweep, a tracking filter (bandpass) is used to filter out of band noise and to ensure a clean harmonic signal. This tracking filter requires a reference so it can follow the excitation frequency. COLA stand for constant output, level amplitude and is effectively a 1Vpk reference signal at the same frequency as the excitation which the acquisition system can use to ensure the tracking filter synchs with the sweep.

With the m+p Analyzer system this is possible via several different methods, but by using time history throughput, you can combine data and benefit from very powerful post processing features.