Shock control

Efficiency

Save setup time with predefined shock geometries such as half-sine, haversine, trapezoid and more. Widely used standards like MIL-STD, DEF STAN, and DO-160 are already included as limits and can be loaded directly – so you can start testing quickly and confidently.

Safety

Protect your specimen and shaker with intelligent safeguards: Peak value checks, multiple displacement compensation methods, and optional drive signal limitations ensure safe and reliable shock testing. In addition, displacement signals are calculated live from acceleration data via mathematical integration, giving you full visibility during every test

Flexibility

Tailor your tests with full freedom: Combine sampling rate and number of samples to define individual window lengths and align the shock within the time window to capture post-shock decay behavior. Adjustable compensation parameters, including pre-pulse tolerance and frequency settings, make even complex setups feasible.

Quality

Achieve accurate and consistent results with high-precision control and complete data storage. Features like IEPE settling time for sensor response, configurable control on every pulse, and live coherence display provide trustworthy insights you can rely on.

Lorem ipsum dolor sit

consectetuer

Individually configurable shock shapes - also imported

Whether half sine, sawtooth, haversine or freely loaded shock shapes - with m+p VibControl, you can flexibly define and visualize the signal shape, velocity and displacement. Direct feedback on the frequency spectrum and shaker load ensures maximum reliability right from the creation stage.

Integrated safety mechanisms protect the specimen and shaker

Visualized shaker load display, scope mode, ICP waiting time and individually definable abort limits ensure a safe test environment - even with high loads and sensitive setups.

Standard compliance down to the last detail - including MIL-STD & Co.

With freely positionable shock pulses in the usable time window and sophisticated displacement compensation, even complex standards such as MIL-STD can be mapped precisely and professionally - including extensive setting options for pre- and post-pulse behavior.

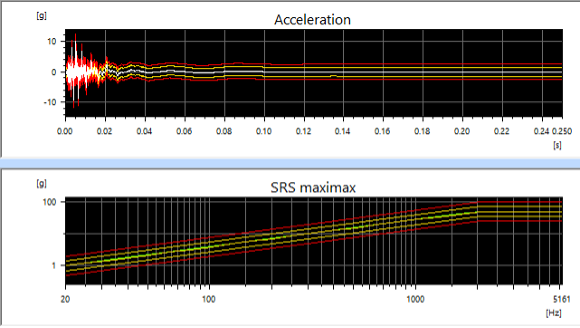

Embedded SRS check for efficient test planning

SRS parameters can be integrated directly into the classical shock test - this allows you to check during execution whether the signal meets the desired SRS curve. This saves time and often also a separate SRS test.

Flexible scheduling - all in one test

Create schedules with pre-levels, repetitions, direction changes and benefit from coherence and error metrics that can be viewed online - including manual fine-tuning with drive signal adjustment for experts.

Update to

m+p VibControl 2.19

Discover how the new features boost

your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for acoustic control

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Sine control resources

SRS Shock testing – FAQ

SRS Shock testing is method of vibration testing where a user has a required SRS profile (waveform) and must generate a complex waveform that can satisfy the user defined SRS requirements. The sythesized pulse can be replicated on a shaker or via custom SRS machine or even a pneumatic hammer system.

Shock Response Spectrum Synthesis is the process of generating a complex time pulse from a series of customisable wavelets. The synthesized pulse is applied to a digital user defined linear SDOF modal in order to asses if the SRS waveform of the synthesized pulse matches the SRS requirements.

SRS synthesis is used when Engineers intended to replicate a synthesized complex shock pulse on a Vibration shaker system, m+p VibControl is a widely used test system for SRS synthesis.