Vector Notching by m+p international

Efficiency

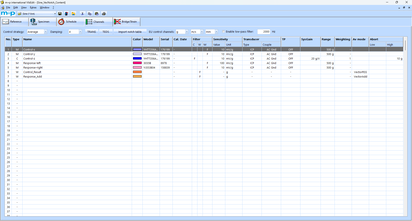

Digital vector addition makes setup simple and eliminates manual calculations. This ensures fast configuration and smooth workflows, even in complex test scenarios.

Safety

Protect both specimen and shaker system from overload: Vector sum notching and momentum notch (overturning moment) provide essential safeguards in force-limited vibration testing.

Flexibility

Extended notch control through vectors gives you more freedom in defining precise protection strategies. Whether on individual channels or combined signals, you adapt the system exactly to your needs.

Quality

Achieve precise and reliable results with advanced vector-based notching. From overall acceleration to overturning moments, Vector Notching ensures transparent and reproducible test conditions for maximum confidence in your data.

Lorem ipsum dolor sit

consectetuer

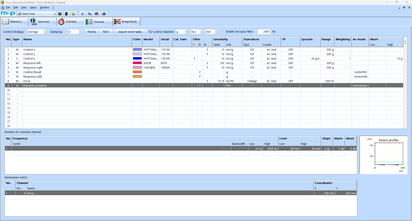

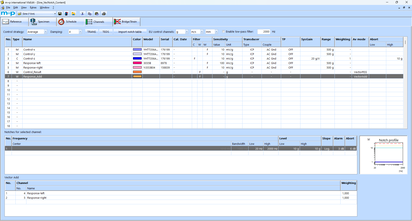

Extended notch control via vectors

Vector Notching enables limitation based on vector variables, i.e. resulting forces or accelerations across multiple directions. Instead of considering individual channels separately, the overall load is determined - for more precise and realistic control in demanding test setups.

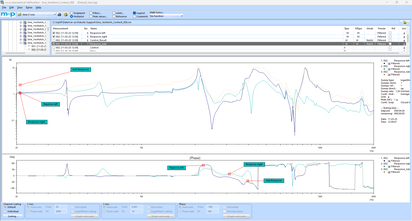

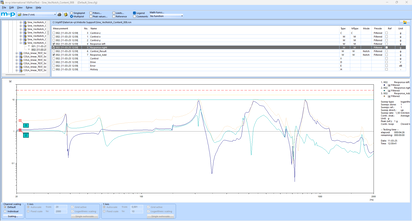

Vector sum - essential for force limited vibration testing

The calculation of the vector sum is a central element in Force Limited Vibration Testing (FLVT). Several force or acceleration sensors are combined mathematically in order to provide a realistic representation of the total load actually acting on the specimen. FLVT can only be implemented safely and reliably using this method.

Notches on the overall acceleration

Vector Notching can be used not only for force channels, but also for acceleration channels - for example to limit the overall acceleration of a component. The combined consideration of all directions effectively protects the specimen from overstressing in multi-axial test environments.

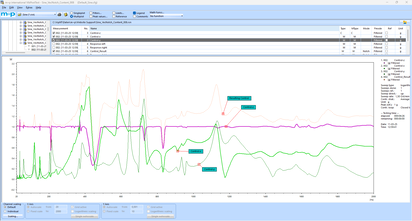

Momentum notch (“overturning moment”)

Overturning momentum notching (also known as “momentum notch”) is used to calculate the torque generated by forces at defined measuring points. This torque can lead to critical loads on the shaker system and slip table, especially during sinusoidal tests. Significant mechanical damage can be prevented by targeted Notching to this value.

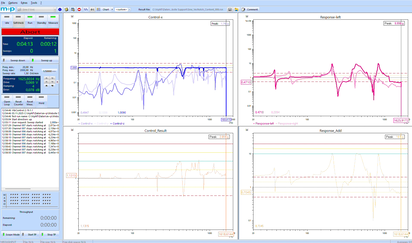

Digital vector addition

Vector Notching enables the digital addition of multiple sensors within the software - without any additional hardware. This eliminates the need for analog cabling, while at the same time ensuring that all sensors operate within their permissible limits. The calculation is carried out in real-time.

Update to

m+p VibControl 2.19

Discover how the new features boost

your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for SensCal

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Shock control resources

Vector Notching / FLVT – FAQ

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.