Our systems support vibration control, shock event capture, environmental integration and certification workflows for railway vibration and mechanical robustness testing. Engineers can qualify components according to IEC 61373, validate rolling stock testing requirements and reproduce operational loads such as ground vibrations from passing trains.

With automated sequencing and advanced analysis, m+p international enables efficient and repeatable test execution across rail applications.

Your Benefits

Ensure safety, reliability and compliance across all railway applications

Advanced Control for Servohydraulic Systems

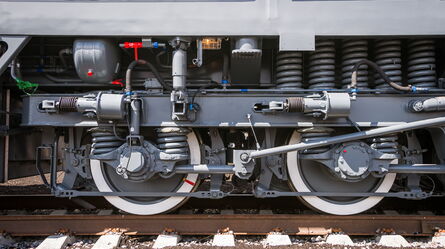

Many railway facilities rely on servohydraulic shakers that offer sine control only. m+p VibControl adds full random control and mixed modes to support railway vibration testing for converters, housings, bogie parts and electronic assemblies. This enables broadband and realistic qualification according to IEC 61373 and other railway standards.

Shock and Drop Test Recording

Railway components must withstand shocks caused by coupling, handling or track events. m+p international systems record high-resolution shock signatures to support train testing and crash-relevant evaluations. Engineers gain clear insight into structural integrity and compliance for certification processes.

Compliance and Certification Testing

m+p international software automates documentation, reporting and data capture to meet railway testing norms. Facilities can generate audit-ready reports for IEC 61373, environmental sequences and mechanical durability requirements, ensuring consistent and repeatable qualification.

Testing of Track and Infrastructure Components

Infrastructure elements such as fasteners, sleepers and signal housings experience ground vibrations from passing trains. m+p VibControl reproduces these loads for durability and fatigue testing, helping engineers assess long-term performance and reduce maintenance risks in railway networks.

Integrated Environmental and Vibration Workflows

Many railway applications require combined environmental and vibration loads. With VibUtil, engineers can synchronize climate chambers and shaker profiles through automated sequencing, enabling efficient multi-stage rolling stock testing with minimal manual interaction.