Road load simulation

Efficiency

Import test signals easily from various formats such as TXT, WAV, or even copy-paste from Excel – setup is fast and straightforward. Flexible resampling options and the ability to cut out dead times keep your tests efficient and focused.

Safety

Protect your specimen and shaker with multiple safety layers: Adjustable ramp-up levels, RMS and peak abort limits, and configurable filters prevent harmful frequency components outside the system’s range.

Flexibility

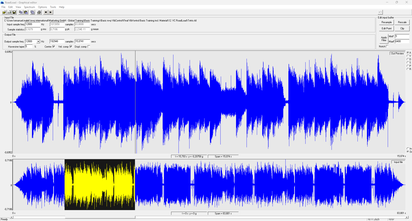

Convert profiles into editable time series, modify them by inserting or removing segments, or generate PSD spectra to replay as random. RoadLoad adapts to your workflow, whether you want realistic roadload time signals or equivalent spectrum-based tests.

Quality

Edit signals with live feedback – apply filters, adjust sampling rates, or trim peaks while directly monitoring the outcome for feasibility and accuracy. Never lose data again: Results are automatically stored even if a test is interrupted, while live error monitoring ensures continuous insight into test quality.

Streamlined workflow:

From raw data to realistic time waveform replication

Flexible file formats - open for your test data

Whether .txt, .csv, .wav or other standard formats: The RoadLoad Editor processes your driving data from a wide variety of sources - without time-consuming conversion or format specifications.

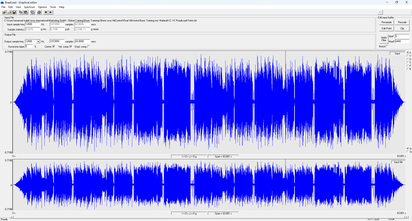

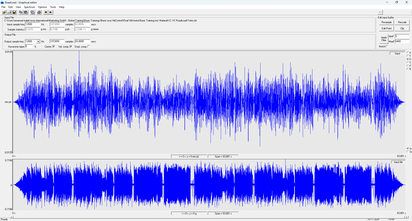

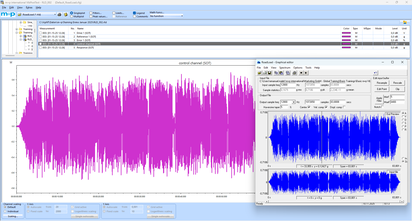

Signal visualization in all dimensions

Acceleration, velocity, displacement and frequency content are displayed in parallel. This gives you an overview of the entire signal behavior - from the raw signal to the spectral analysis.

Efficient signal processing for realistic tests

Truncate peaks, remove dead times, apply windowing, isolate or repeat sequences: the editor allows you to adjust the signal in a targeted manner to make optimum use of shaker performance and shorten test times.

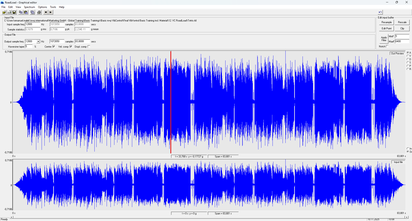

Live position display in the signal - ideal for long tests

Integration with the VibRunner shows in real-time where you are in the time signal. Particularly helpful for long or repeated driving cycles.

Realistic reproduction on the shaker

With the RoadLoad Controller, the processed signal is reproduced realistically on the test bench - precisely tuned, safe to perform and documentable in a compliant manner.

Update to

m+p VibControl 2.19

Discover how the new features boost

your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for road load testing

Services

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Road load simulation resources

Road load simulation – FAQ

Road Load Data (RLD) is real-world vibration data measured from a product during actual use, usually collected using accelerometers, strain gauges, load cells, or other transducers mounted on the product or vehicle.

It represents the true dynamic environment your product experiences in the field and is the foundation for designing accurate and not-overly-conservative vibration tests.

In vibration testing, this usually means acceleration time histories recorded while driving on real roads, but the term applies broadly to:

- automotive components

- agricultural machinery

- construction equipment

- aircraft

- maritime equipment

- consumer electronics

- defense systems,

Road Load Data Acquisition (RLDA) is a process of collecting real-world vibration data from a vehicle while driven in field. Sensors attached to the vehicle collect raw (long) time history data that can analysed and post processed after wards.

Engineers need to know what loads a vehicle or part will encounter on real roads to design reliable components. RLDA provides this by capturing the true dynamic environment, which can then be reproduced in the lab.

- Instrumenting the vehicle

Sensors are mounted on the vehicle or component, such as:- Accelerometers

- Strain gauges

- Load cells

- Displacement sensors

- Driving through real-world conditions

The instrumented vehicle is driven on:- Highways

- City roads

- Rough tracks / proving grounds

- Potholes, bumps, cobblestones

- Off-road terrain (if relevant)

This captures the full spectrum of vibration and load inputs.

- Collecting and storing data

The data acquisition system records:- Accelerations

- Strains

- Forces/moments

High sampling rates are used to capture high-frequency vibrations.

- Processing the data

After collection, the raw signals are processed to:- Remove noise

- Identify events (bumps, potholes, braking, etc.)

- Convert signals into load histories

- Reduce data to a representative test (data reduction)

- Generate drive files for lab testing (like for shaker rigs or multi-axis simulators)

Time waveform replication is an alternative name to road load data replication. It involves the same process as road load testing but applies to a broader range of industries, such as Aerospace, Defence, Space & etc.