Electronic products must withstand vibration, temperature, and humidity stresses while meeting strict global compliance requirements. We help you build certification confidence when performing electronics vibration testing, thermal and humidity sequences, electronic product testing, and structural analysis for PCBs, consumer devices, batteries, lighting systems, and control electronics.

Our solutions allow you to identify design, assembly, and handling issues early, qualify products to international standards, and reduce costly field failures. With scalable hardware, advanced visualization, and broad data integration, we deliver fast, repeatable, and compliant electronics environmental testing across all development stages – trusted by global brands such as Bosch, Siemens, and leading automotive OEMs.

Your Benefits

High-precision vibration and environmental testing for electronic products

Flexible Testing for Any Size Application

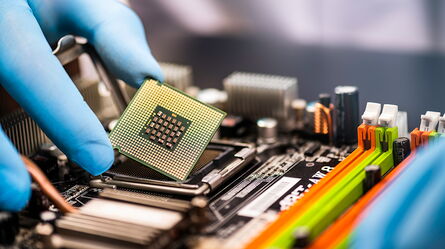

m+p international solutions work with any shaker that accepts signal input, supporting everything from small PCB-level tests to high-channel system qualification. This enables efficient and cost-effective vibration testing for electronic equipment without investing in oversized hardware. Engineers can switch between boards, subassemblies and full devices while maintaining precise control and stable test execution.

Accurate Non-Contact Vibration Measurement

Delicate PCBs and lightweight components are highly sensitive to added mass. Our systems support non-contact transducers, such as laser vibrometers, enabling accurate characterization of resonances without altering structural response. This ensures reliable electronic components testing and prevents measurement-induced shifts in frequency behavior.

Dynamic Behavior Visualization to Prevent Failures

Visualize how PCBs, connectors, and assemblies move under excitation using operational deflection shapes. Overlay charts, compare multiple signals, and use dual-axis plots to pinpoint mounting weaknesses, resonance-driven failures, and critical subcomponents. These insights speed up design improvements and strengthen reliability testing of electronic components and assemblies.

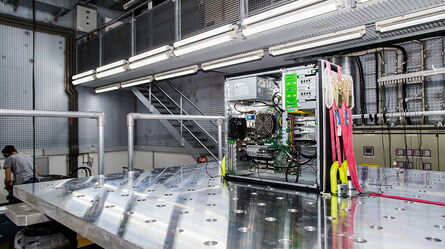

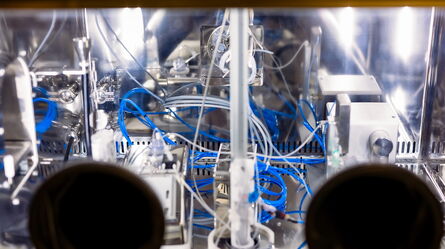

Integration of Climatic, Vibration and Monitoring Systems

Modern electronics require combined testing. Our solutions integrate vibration profiles with temperature, humidity and external monitoring equipment. REST API connectivity supports automated workflows, communication with PCB drive systems and full control of environmental conditions for electronics reliability testing and qualification programs.

Accelerated Life and Aging Tests

Manufacturers can perform accelerated life testing electronics, accelerated aging test for electronics and stress screening to uncover early-life failures. Controlled vibration, thermal cycling, and humidity exposure reveal latent issues, helping teams improve long-term reliability and reduce warranty returns in consumer electronics reliability testing.

Comprehensive Data Handling and Compliance

Flexible import and export options support industry formats and allow seamless integration with customer systems. Automatic reporting, throughput logging, and time-history storage ensure full traceability for vibration testing standards for electronic equipment. This simplifies audits, accelerates documentation, and enhances customer confidence.