Your safeguard for critical tests and processes

Reliable

Rely on continuous, fail-safe monitoring with automatic safety loops and immediate alarm triggers to protect your equipment and test objects.

Compliant

Meet stringent ISO and aerospace/defense requirements for thermal vacuum and structural testing with built-in standard support.

Accurate

Capture high-precision strain, temperature, and force data with sample rates up to 200 kHz and full alias protection.

Scalable

Expand your set-up from 2 to several thousand measurement channels, tailoring the system to anything from small lab tests to large-scale testing facilities.

Flexible

Pair the software with our m+p VibRunner and m+p VibPilot DAQ systems, or third-party hardware like NI and VTI.

Safe

Prevent damage to specimens and test equipment with an independent safety loop that triggers automatic shutdowns during critical events.

Integrated

Combine your data acquisition, automation, and condition monitoring into one powerful software.

Future-proof

Grow your testing capabilities through a modular design that lets you monitor new sensors and environments without re-programming.

Smart monitoring from setup to safety

Fast Set-up

Begin measuring in minutes with automatic hardware recognition and configuration that eliminates manual setup delays.

Accurate Data Acquisition

Capture analog and digital signals from any DAQ system and mixed hardware platforms with flexible multi-rate sampling ranging from 1 Hz to 200 kHz and synchronized time-stamping.

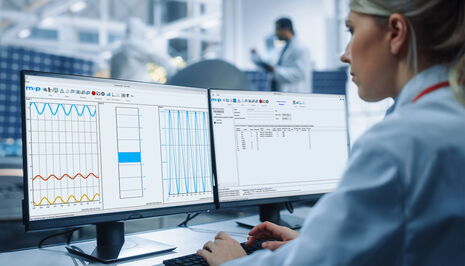

Real-Time Monitoring

Visualize temperatures, strain, pressures, and forces instantly while leveraging trend calculations, warning levels, and abort limits to stay in control.

- Structural Monitoring: Monitor forces, accelerations and facility conditions with independent safety loops and automatic shutdown.

- Stress and Strain Measurement: Record ¼, ½ and full bridge gauges or rosettes; perform real-time principal strain calculation and trend analysis.

- Thermal Monitoring: Measure temperatures, pressures and voltages for thermal vacuum or environmental simulation tests.

Safe Event Handling & Automation

Trigger automated reactions via digital and analog I/O or OPC UA/DA based on your predefined thresholds. m+p CODA protects your investment by automatically pausing or aborting tests before damage occurs.

Instant Reporting & Integration

Export data and full metadata to CSV, Excel, MATLAB, UFF and UVN or share directly with m+p Analyzer or m+p VibControl to ensure total traceability and simplify model validation.

Test monitoring for your application

Complete monitoring set-ups

Scalable hardware for turnkey systems

Combine m+p Coda software with our measurement hardware made in Germany. These modular DAQ systems can be scaled for any needs for a complete DAQ and safety setup.

- m+p VibPilot – Compact DAQ systems

- m+p VibRunner – High channel count DAQ systems

Enhanced Test Supervision

Integrate m+p Coda software seamlessly with our vibration controllers to enable parallel test supervision and independent shutdown capabilities. This dual-layered approach protects your valuable assets with real-time monitoring and an independent failsafe layer.

Scalable Lab Architectures

Extend your testing reach to thermal vacuum, structural, or durability labs using distributed DAQ architectures.

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

What customers say about

m+p Coda

Test Monitoring Resources

Upcoming events

Test Monitoring FAQ

m+p CODA monitors and records test data from any DAQ system in real time and protects specimens and equipment.

Yes – m+p CODA operates as an independent safety loop and can interface with any controller via digital I/O or OPC.

m+p CODA measures analog inputs for strain, force, pressure, temperature, voltage and digital I/O signals for control and event handling.