Notching by m+p international

Efficiency

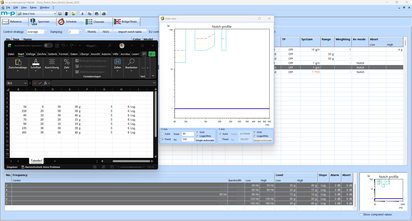

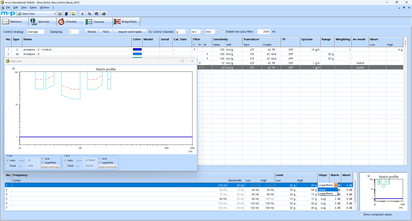

Clear graphical displays and external configuration options make setup fast and straightforward. You immediately see how limits apply, saving valuable time during test preparation.

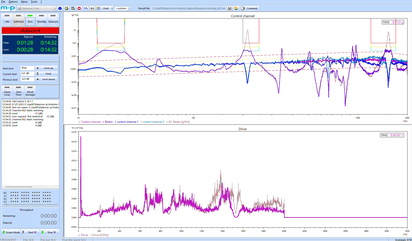

Safety

Sensitive specimens remain fully protected: Reliable notching prevents overloads by keeping excitation within safe boundaries – no matter how demanding the test.

Flexibility

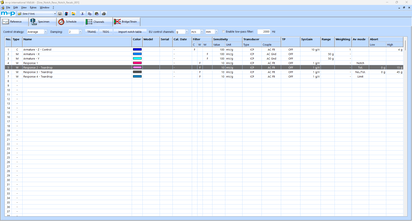

Define up to 50 individual limiting spectra and adapt them to your excitation type – from sine to random or shock. Combine notching, tolerance, and limit modes to create exactly the protection concept your test requires.

Quality

Trust in precise, transparent protection mechanisms. The combination of multiple limiting methods and clear graphical visualization ensures reproducible results and complete confidence in your test data.

Lorem ipsum dolor sit

consectetuer

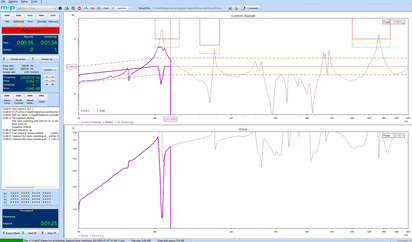

Reliable protection for sensitive specimens

By specifically limiting amplitudes in defined frequency bands, Notching reliably prevents structural overloads - even in the event of unpredictable resonance effects.

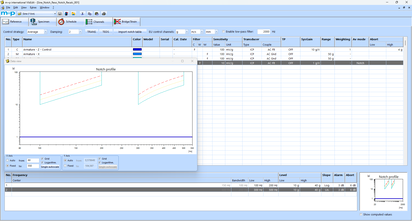

Flexible definition of up to 50 limiting spectra

Limiting spectra can be defined via center frequency and bandwidth or directly via minimum and maximum frequencies. Linear, logarithmic or RMS-based slopes are available.

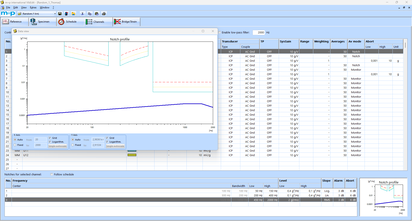

Combinable protection modes: notch, tolerance, limit

Different protection strategies such as pure limitation (notch), mixed tolerance limits with warning/cancel function or automatic limits for resonance shifts enable precise adaptation to the testing needs

Adjustable depending on excitation

The notch parameters can also be configured individually depending on the excitation mode - for example, RMS-based in the random test, narrowband in the RoR or frequency-selective for superimposed sine components in SoR tests.

Update to

m+p VibControl 2.19

Discover how the new features boost

your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for notching

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Notching resources

Notching – FAQ

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.

Lorem ipsum dolor sit amet. Vel quis assumenda ad iusto cupiditate nam quia nemo in Quis dolorem. Ex rerum amet qui corporis odit est exercitationem sequi.