Your Benefits

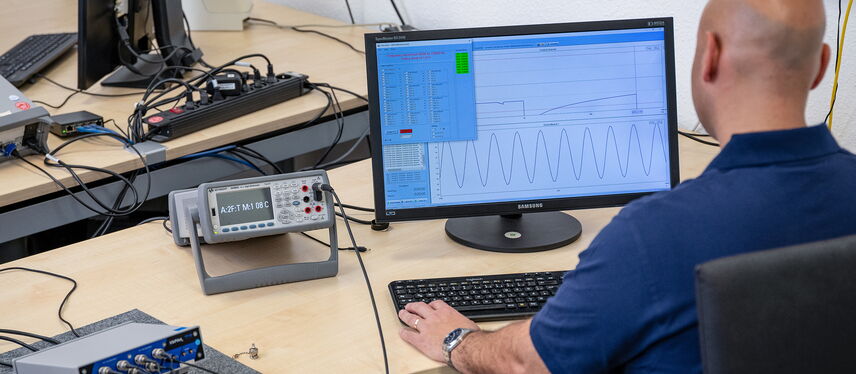

Regular calibration of your m+p international hardware ensures accurate testing and prolongs your equipment lifespan.

Enhance measurement confidence:

Sustain the accuracy and precision of your equipment for valid results.

Guarantee compliance:

Maintain traceability to national and industry standards.

Confirm system functionality:

Verify that your measurement system is operating as expected and identify potential issues before they impact your work.

Avoid costly consequences:

Inaccurate measurements can cause unplanned downtimes of your test equipment or even lead to expensive repercussions, such as product recalls.

Choose your calibration

Factory calibration

With this choice our service team calibrates your devices at the m+p international facilities. An extensive system check is included.

What you will receive

- Calibration performed by m+p international according to product specifications

- using reference standards traceable to DAkkS/ISO 17025

- with a detailed calibration protocol provided

ISO 17025 calibration

In many industries, calibrations based on the international standard for testing laboratories are essential for smooth audits. Choose this service to ensure compliance and demonstrate your commitment to quality.

What you will receive

- System calibrated by an DAkkS / A2LA accredited laboratory

- according to ISO / IEC 17025

- with a detailed calibration certificate provided

Options to keep your lab running

On-site calibration

Our service engineers come to your laboratory and calibrate your measurement systems on-site. Choose the certification standard you require: factory or ISO 17025.

What you will receive

- Saves valuable time usually required for disassembly, transit and reassembly of your systems

- Increases comfort by eliminating the hassle of logistical efforts

- Avoids risks associated with the shipping of sensitive equipment

Rental systems

We provide equivalent rental systems while your measurement hardware is being calibrated at our facilities. Explore our maintenance contract options for priority access.

What you will receive

- Maximizes laboratory uptime by only requiring the time necessary for equipment exchange

- Budget-conscious option to bridge calibration gaps

Calibration FAQ

Calibration frequency for measurement hardware can be based on internal quality management guidelines or industry standards such as EN/ISO IEC 17025.

We recommend annual calibration as a general guideline to maintain accuracy and reliability.

Consider calibrating more frequently in these situations:

- Changes to the measuring chain (e.g., new sensors, software updates)

- Reaching a certain number of operating hours

- Changed environmental conditions (e.g., temperature fluctuations, humidity)

- Upcoming performance of a critical measurement

Check the calibration sticker on your system for the recommended month and year of the next calibration. Be aware:

- Factory calibration stickers indicate the next due date.

- ISO/IEC-17025 (DAkkS / A2LA) calibration stickers show the last calibration date.

To avoid disruptions to your workflows we advise to plan your next calibration immediately after the current one is completed. This prevents scheduling conflicts and helps to ensure rental system availability if required.

If scheduling this early should not be an option for you, aim to plan your calibration 3 months in advance.

The calibration turnaround time at our facilities is typically 2-7 days. However, shipping can significantly add to the overall downtime. To minimize disruptions, schedule your calibration during periods of reduced workload, such as vacation times. For faster and more convenient options, explore our rental system or on-site calibration services.