Random vibration control

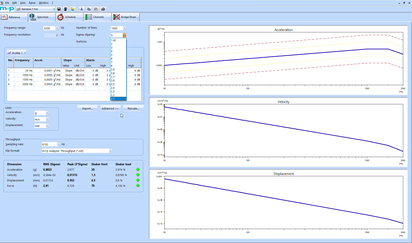

Efficiency

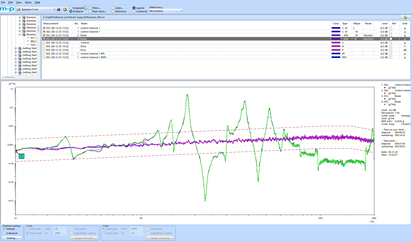

Get tests up and running quickly and keep them efficient: Direct RMS display, easy PSD (power spectral density) adjustments without reprogramming, and automatic storage of intermediate results ensure smooth workflows, even in long-term testing.

Safety

Count on reliable protection for your system and specimen. Peak value checks, RMS drive limitations, and smart shutdown options safeguard your tests against overload and damage.

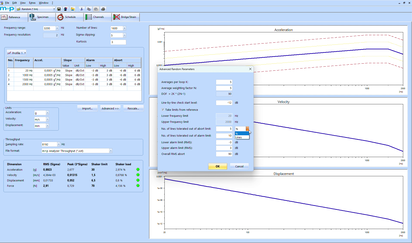

Flexibility

Shape your test the way you need it: Define signal processing, choose between arithmetic or moving averages, or intervene manually to ramp levels. Random gives you full control – from automated runs to hands-on fine-tuning.

Quality

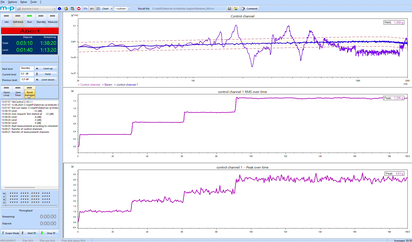

Rely on high-precision control and secure data at all times – Never lose data again, even if a test is interrupted. With RMS-over-time, multi-point control, and online monitoring, you gain trustworthy results and can easily demonstrate compliance in demanding long-duration tests.

Precision control for demanding random vibration testing

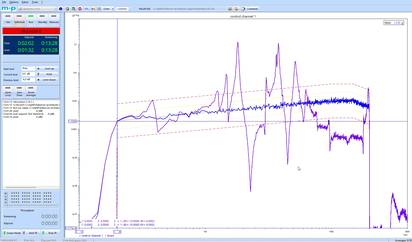

Maximum test control for maximum safety

Numerous adjustable parameters such as spectral lines tolerances, RMS abort limits and flexible sigma clipping enable random vibration tests to be adapted exactly to the test requirements - for maximum safety for critical components.

Standard-compliant testing beyond the excitation frequency

With the option of defining the frequency range beyond the actual excitation frequency, even demanding standards for random vibration testing such as DIN EN 60068-2-64 can be met reliably and reproducibly.

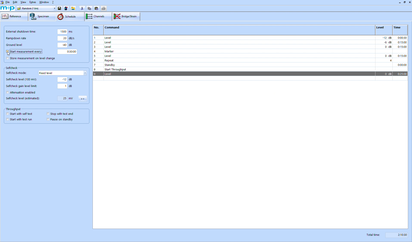

Individually configurable test sequences

Thanks to a flexibly configurable schedule with freely definable pre-levels, loops, random vibration profile changes and time control during measurement, every random vibration test can be tailored exactly to the test target - without any compromises.

Flexible averaging methods for meaningful results

Exponential or arithmetic averaging - the optimum method can be selected depending on the test objective, for example for smoothing transients or gaining significant signal components. This is ideal for precise assessment even with strongly fluctuating signals.

Transparency and traceability in real-time

The display of RMS and peak values over time, live refreshed PSDs and level and remaining time displays ensure maximum transparency. Measurements can be reset at any time to eliminate special effects if necessary.

Update to

m+p VibControl 2.19

Discover how the new features boost

your vibration testing.

Scalable measurement hardware systems - from 4 to hundreds of channels

m+p VibPilot - Compact DAQ systems

Choose our powerful, lightweight, and fan-less m+p VibPilot measurement front-end for all test setups with 4 or 8 channels and combinable for up to 32 channels, whether in vibration testing or in vibration and sound analysis.

m+p VibRunner - High channel count DAQ systems

Test large structures or applications with high data throughput using our modular m+p VibRunner hardware platform that can be flexibly scaled to handle hundreds of input channels or multiple exciters.

Applications for random vibration tests

Random vibration testing services

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

Case studies

Mahle Filtersysteme | DE

Engineering tests for vehicles airfiltration and engine components

Aerospacelab

A cutting-edge vibration test system

Element laboratory | UK

Shake and bake testing for aerospace components

China Electronics Technology Group Corporation | CN

Radar reliability testing

Random vibration test resources

Random Vibration – FAQ

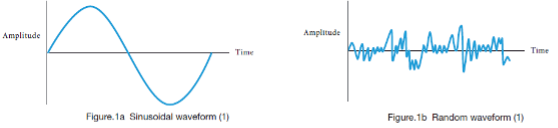

Sinusoidal vibration is a representation of simple form of motion,’ as its deterministic, its frequency content and amplitude are defined, so ‘the motion of vibration can be predicted at any point in time’, due to its periodic nature.

A pure sine waveform is composed of a signal frequency at a given moment, while a Random vibration is characterised as non-deterministic motion, which is composed of a multitude of frequencies excited at the same time, as a result its future behaviour cannot be predicted based on its past behaviour (aperiodic nature).

Random vibration is recognized as a more realistic approach of simulating the effects vibrations have on objects/systems in the real world compared to Sine Vibration testing.

Random vibration testing is a test method used to simulate random forces & vibrations on test product to assess its durability in a laboratory environment. Consider the example of simulating the vibrations induced on a car battery while driving. The battery will be subjected to vibrating motion from the car chassis, the road surface, the cars gears turning and etc. None of the motions mentioned are deterministic, due to the fact road surfaces are uneven as you drive, and the speed of the car is never really constant, as well as many other random processes.

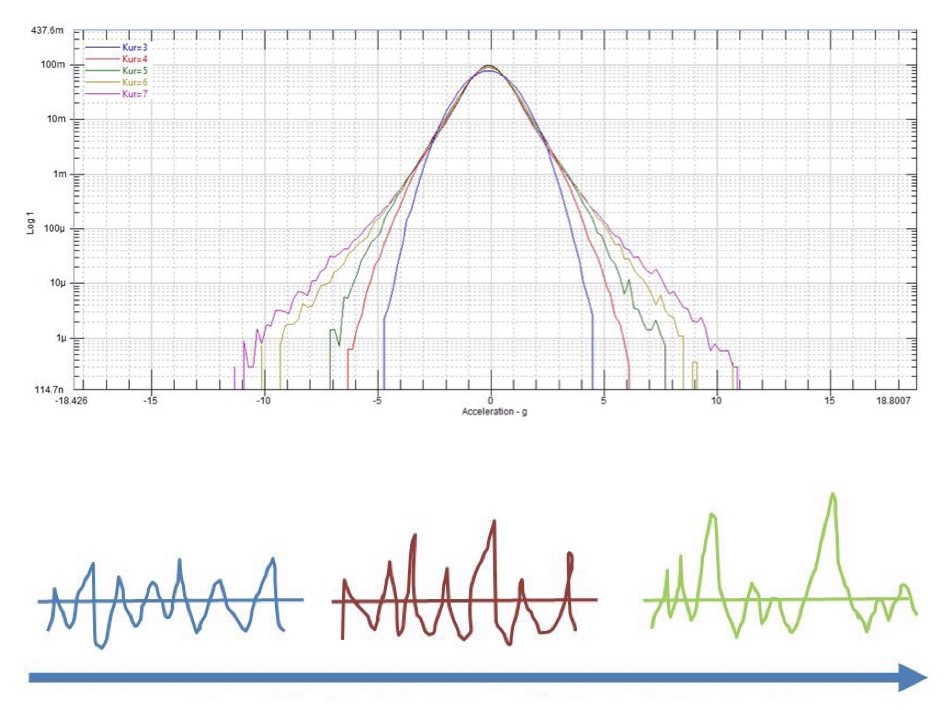

Kurtosis is a mathematical concept that can alter a Probability Density function to increase the chance of higher peak events occurring during a Random Vibration test, while retaining the same energy content as a Gaussian Distribution. Lets break this down in the concepts below:

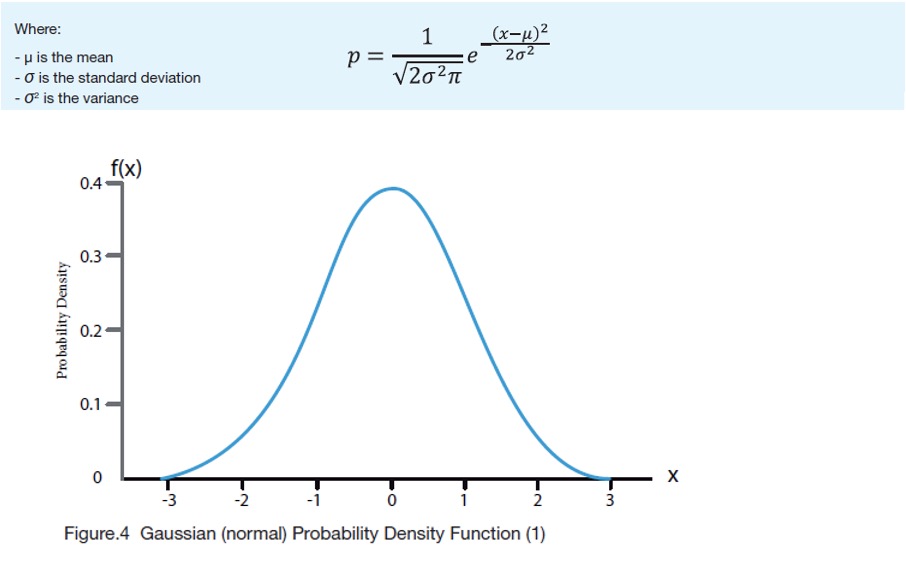

There is no true mathematical equation to represent a random vibration, but the probability of the occurrence of amplitude events within a range of values can be statistically predicted, using a Probability Density Function. ‘The most commonly used probability distribution is the normal (Gaussian) distribution’, which is mathematically expressed as:

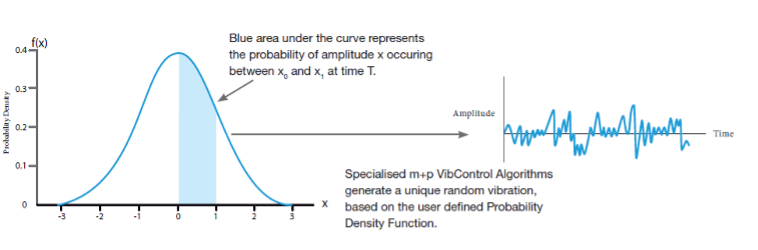

Within vibration testing the Gaussian (normal) distribution has been the set standard of defining a Probability Density Function, which is used to generate a random signal based on the statistical probability of an amplitude event occurring within a given range, as per example below:

For vibration testing a normal gaussian distribution has a Kurtosis of 3. Increasing the value of Kurtosis increases the ‘heaviness’ of the tails of the amplitude distribution, which in turn increases the probability of peak events occurring in the generated random vibrations in comparison to a Gaussian Probability Density Function.

Increasing Kurtosis results in higher amplitude events occurring in random vibrations

A PSD (Power Spectral Density) is a type of spectrum that defines the probability of the frequency contents in a time signal. The units of a PSD are g2/Hz. it is a statistical evaluation of a time signal in the frequency domain, where in theory the time signal is endless and also the observation time is endless. The rms signal level of a Random vibration is derived from the area under a given PSD curve.

In random vibration testing we use a probability density function to generate a random signal based on the statistical probability of an amplitude event occurring within a given range.

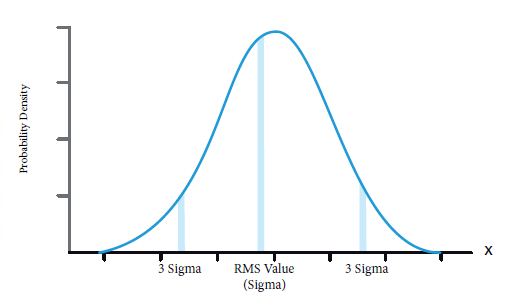

The RMS value of a random vibration is the Sigma value of a Probability Density Curve. This is only possible because the mean of the distribution is 0. Peak values of Random Vibrations are derived from the RMS value, where 3 Sigma represents 3 times the RMS value. So for a 1grms test the 3 sigma value would be 3 g’s.

ASD is Acceleration Spectral Density and PSD is the Power Spectral Density. Both terms are essentially the same thing and can be used interchangeably with one another. PSD is a more general term for a frequency spectrum, while ASD is more commonly used to describe a frequency spectrum associated with Random vibration testing.