Smart automation, superior output

Economical

Maximize lab throughput by 30–50% through unattended execution. Lower integration costs and simplify maintenance using unified standard interfaces to connect with other test tools.

Error-free

Ensure end-to-end traceability. Reduce human error and Improve consistency and documentation across all setups for full compliance.

Integrated

Bridge the gap between fragmented test tools and vendor software for a fully synchronized test environment via Open integration with MES, ERP, and data lakes.

Future-proof

Invest in future-proof test automation based on open architecture that grows with your needs – from simple Python scripts to complex, enterprise-level CI/CD pipeline integrations.

How our automation tools boost your test laboratory

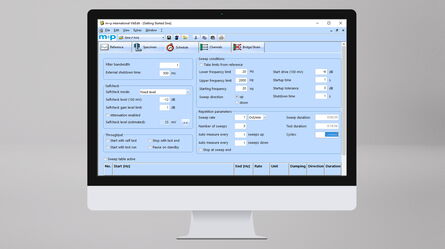

Automation links all m+p international solutions to create continuous, closed-loop workflows. It’s the foundation of the digital test lab, enabling traceable data, reproducible processes, and seamless integration with enterprise systems.

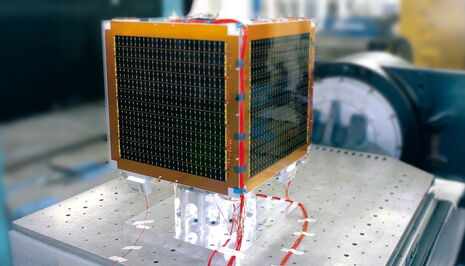

Maximize laboratory throughput

Lab Managers leverage unused test capacity by running automated vibration test sequences as batches overnight or during weekends. This is especially effective for long test cycles, dramatically increasing overall shaker utilization and saving operator time.

Reduce manual setup effort and errors

Programming interfaces connect our vibration control and analysis solutions to external systems, enabling comprehensive task automation. This enables significant time savings for Test Engineers and eliminates human errors during test setup and data transfer.

Ensure end-to-end traceability

Quality Engineers are able to automate data acquisition and analysis using scripted reporting and digital I/O control. This guarantees consistent, repeatable results across all setups and ensures full compliance for audit readiness.

Accelerate digital twin validation

R&D Managers seamlessly use real-time automation data to feed simulation loops, significantly speeding up the development and validation of Digital Test Twins.

Lower integration costs and simplify maintenance

System Integrators benefit from unified automation across the m+p international ecosystem. We utilize standard REST interfaces instead of custom drivers to connect our solutions with other test tools, drastically reducing integration costs and ongoing maintenance efforts.

Ready to automate your test lab?

Let’s design your automation strategy — from single system integration to full digital workflows.

Applications

Services

Support

We offer personalized support from experts with excellent response times, not anonymous call-centre hotlines.

Calibration

Choose between factory and ISO 17025 calibrations with on-site and rental services to minimize downtime.

Training

Our experts help you train new employees, master new testing challenges, or optimize specific test processes.

Maintenance Contracts

Let us take care of hardware calibration and software updates so you can focus on your tests.

What customers say about our automation solutions